Ultra High Purity (UHP) Valve Market to Reach USD 1,155.2 million by 2035, Fueled by Semiconductor and Pharma Growth

Global UHP Valve Market to hit USD 1,155.2 million by 2035 at 6.5% CAGR, driven by semiconductor and pharmaceutical manufacturing expansion.

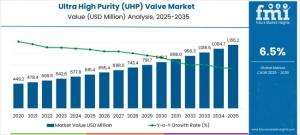

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The global Ultra High Purity (UHP) Valve Market is projected to grow from USD 615.4 million in 2025 to USD 1,155.2 million by 2035, registering a 6.5% CAGR. The rise is primarily driven by the rapid expansion of semiconductor manufacturing, pharmaceutical production, and chemical processing, where precise fluid control and contamination-free environments are critical.

UHP valves, engineered for stringent purity standards, play an indispensable role in high-technology industries where reliability, precision, and cleanliness define operational success.

Market Dynamics and Growth Insights

The UHP valve market’s expansion aligns closely with the semiconductor industry’s growth trajectory, which demands ultra-clean process control systems. From USD 449.2 million in 2023 to USD 615.4 million in 2025, the market has demonstrated robust year-on-year gains, with forecasts suggesting consistent acceleration throughout the decade.

The integration of advanced materials, improved sealing technologies, and digital monitoring systems is transforming valve design. Manufacturers are increasingly focusing on smart valve technologies with IoT-based predictive maintenance, ensuring real-time diagnostics and extended service life.

Between 2025 and 2030, the market is expected to reach USD 843.2 million, progressing steadily toward USD 1.15 billion by 2035. The decade-long forecast highlights how industrial expansion, process automation, and precision engineering continue to shape this high-performance equipment market.

Segmental Outlook

By Material Type

- Steel Valves are projected to hold 36.1% of the market share in 2025, valued for their corrosion resistance and mechanical durability.

Advances in surface finishing and alloy purity have enabled superior contamination control, aligning with the demanding standards of semiconductor and biopharmaceutical sectors.

- Fluoropolymer Valves are gaining traction for their chemical compatibility in corrosive environments, particularly in LCD, PV, and chemical processing applications.

By End-Use

- Semiconductor Processing remains the leading end-use segment, accounting for 52.8% of demand in 2025.

Modern fabs require UHP valves for process gas control, ultrapure water, and chemical distribution systems. With advanced node technologies below 5nm, contamination levels are monitored in parts per billion (ppb), underscoring the importance of valve precision.

Regional Insights – Ultra High Purity (UHP) Valve Market (2025–2035)

Asia-Pacific Leads Global Expansion

- The Asia-Pacific region dominates the UHP valve market, driven by massive industrialization, semiconductor fabrication growth, and advanced manufacturing infrastructure.

- China and India are the key contributors, together accounting for the largest share of global market growth.

China – Fastest Growing Market (CAGR: 8.8%)

- Rapid expansion of semiconductor fabrication facilities and government-backed technology localization programs.

- Strong policy support under national semiconductor strategies and clean manufacturing initiatives.

- Increasing domestic production of high-purity components to reduce import dependence.

India – Strong Growth Momentum (CAGR: 8.1%)

- Driven by “Make in India” and Production-Linked Incentive (PLI) schemes supporting electronics and pharma manufacturing.

- Surge in pharmaceutical production and foreign investments in high-tech industries.

- Growing demand for contamination-free flow systems in bioprocessing and semiconductor assembly.

Germany – Engineering and Quality Hub (CAGR: 7.5%)

- Growth supported by precision engineering excellence and advanced manufacturing capabilities.

- Widespread use of UHP valves in semiconductors, pharmaceuticals, and specialty chemicals.

- Strong R&D programs focused on next-generation valve designs and surface treatments.

Brazil – Emerging Regional Market (CAGR: 6.8%)

- Expanding pharmaceutical and electronics manufacturing sectors.

- Industrial modernization programs driving adoption of high-purity components.

- Increasing investments in infrastructure and clean production technologies.

United States – Innovation-Driven Market (CAGR: 6.2%)

- Leadership in semiconductor technology, supported by CHIPS Act investments.

- High adoption in pharmaceutical and biotechnology applications.

- Strong ecosystem for R&D collaboration and smart valve technology development.

United Kingdom – Biotechnology Expansion (CAGR: 5.5%)

- Growth supported by biotech research, life sciences funding, and specialty chemical manufacturing.

- UHP valves increasingly used in sterile and precision chemical processing environments.

Japan – Mature but Stable Market (CAGR: 4.9%)

- Renowned for precision manufacturing expertise and semiconductor process innovation.

- Strong focus on miniaturization, surface quality, and high-accuracy components.

- Continued innovation through industry–academia R&D collaborations.

China leads with the fastest growth, driven by state-backed semiconductor investments and national strategies promoting technological self-reliance. Similarly, India’s focus on electronics and pharma manufacturing under national programs is attracting global UHP valve suppliers.

In Germany, precision engineering and R&D leadership fuel continuous innovation, while the United States benefits from advanced semiconductor initiatives such as CHIPS Act-funded fab expansions.

Market Drivers and Key Trends

Semiconductor Expansion: As chip manufacturing moves to smaller geometries and advanced packaging, process purity requirements intensify. UHP valves ensure contamination-free flow control for gases and chemicals essential to chip yields.

Pharmaceutical Process Optimization: In sterile and biopharma environments, UHP valves maintain validated purity standards, supporting cell culture, vaccine production, and biological material handling.

Smart Valve Integration: Modern valves now feature real-time data monitoring, predictive analytics, and AI-driven diagnostics, enabling process optimization and reduced downtime.

Material Innovation: Manufacturers are investing in fluoropolymer coatings, ultra-clean steel alloys, and surface engineering to meet the rigorous purity demands of high-tech industries.

Competitive Landscape

The UHP valve market remains consolidated around global leaders emphasizing material innovation and process reliability.

Key Companies:

- Parker Hannifin (USA) – Advanced materials and semiconductor-grade valve systems.

- Swagelok (USA) – Comprehensive high-purity flow solutions and service support.

- CKD Corporation (Japan) – Precision valve technology for ultra-clean processes.

- SMC Corporation (Japan) – Pneumatic and fluid control solutions for cleanroom applications.

- Entegris (USA) – Specializes in contamination control technologies.

- TK-Fujikin (Japan) – High-performance precision valves for semiconductor fabs.

- Saint-Gobain (France) – Advanced polymer-based valve materials for critical applications.

Strategic collaborations, localized assembly, and R&D-driven innovation are key differentiators enabling these players to address global supply chain and contamination control challenges.

Explore the full market insights and future trends—read the complete Market Report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-26975

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/26975

Future Outlook (2025–2035)

The next decade for the UHP valve market will be defined by technological precision, sustainability, and digital integration. As semiconductor fabs and biotech facilities grow in complexity, UHP valve manufacturers that combine smart sensing technologies, advanced materials, and global service networks will capture the largest market share.

By 2035, UHP valves will not only serve as contamination-control devices but as intelligent process components integral to real-time manufacturing optimization.

Related Reports:

Turbidimeter Market- https://www.futuremarketinsights.com/reports/turbidimeter-market

Tire Curing Press Market- https://www.futuremarketinsights.com/reports/tire-curing-press-market

Pin Marking Machine Market- https://www.futuremarketinsights.com/reports/pin-marking-machine-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.